Four practical case examples of pattern recognition in Wedge

Wedge makes it possible to use advanced algorithms to recognize patterns in process and quality data. Below, we have introduced four practical applications of pattern recognition that help Wedge users to gain a better understanding of cause-and-effect relationships within the process.

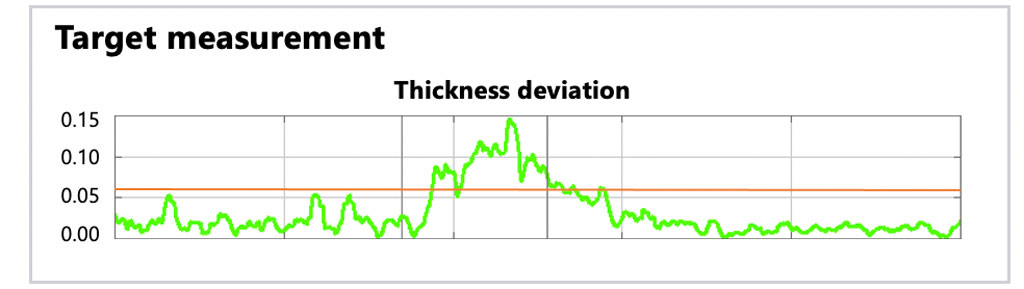

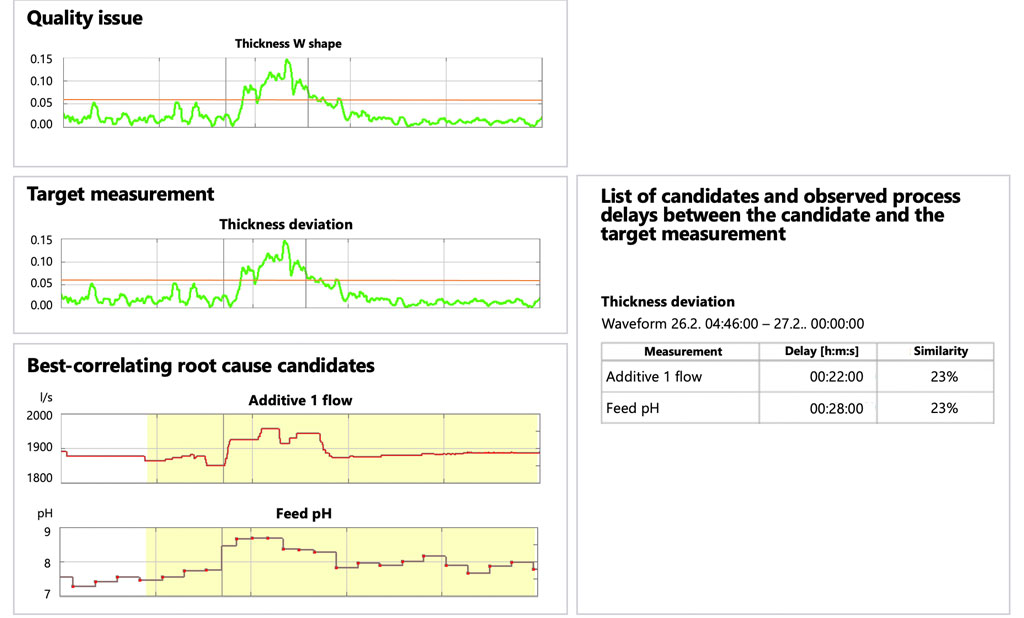

CASE 1: Trace the root cause of a quality issue

There is a quality issue in your process. Deviation occurs in the thickness of the end product, causing waste and scrap. Your first priority is to understand what the underlying causes are that impact the thickness deviation.

Wedge goes through all the other measurements and finds the ones that have a similar or mirror pattern at the same time or before the thickness deviation. As a result, the Wedge system lists the root cause candidates for the quality issue.

As a Wedge user you do not have to worry about possible process delays, since the pattern recognition tool compensates for them automatically.

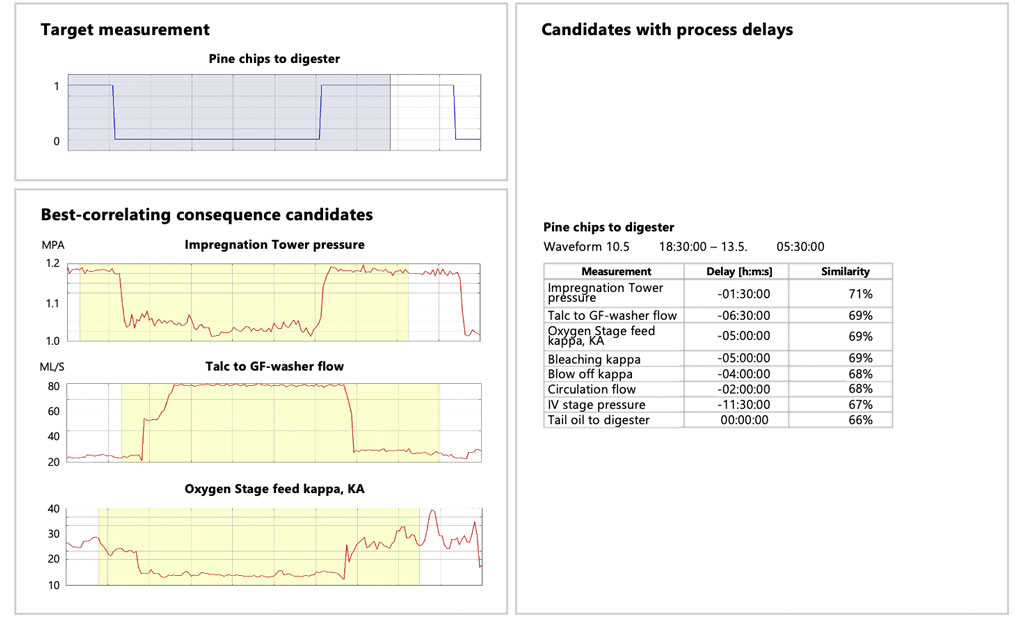

CASE 2: Understand the consequences of raw material changes

Changes in raw material may also affect your process. Wedge pattern recognition algorithms can also help you find those.

Wedge compares the shape of the target measurement (the change of raw material from type one to zero, and back to one) to other signals, and lists the best-correlating consequence candidates with regard to the target measurement and process delay.

This is a great way to learn new things about the behavior of the target process.

CASE 3: Figure out what causes periodic fluctuations

A single peak in a signal and/or a change in a level are easy patterns to notice and trace. But what if your target measurements fluctuate strongly but it seems to be random? Or the pattern does not look clear or there are several independent patterns having an impact at the same time? Sounds complicated, but with Wedge it is not.

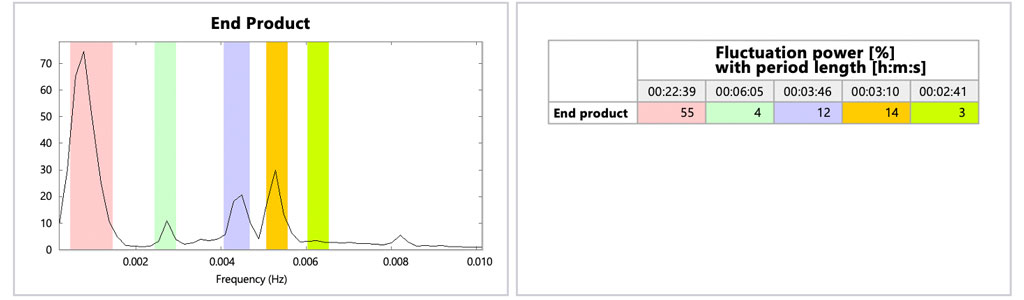

First, Wedge helps you by isolating different patterns from the signal. The system shows what kinds of fluctuation patterns can be found and the relative power of each pattern. In practice, we get to know whether there are periodic fluctuation patterns in the data, what the period lengths of the identified patterns are, and which fluctuation is the strongest.

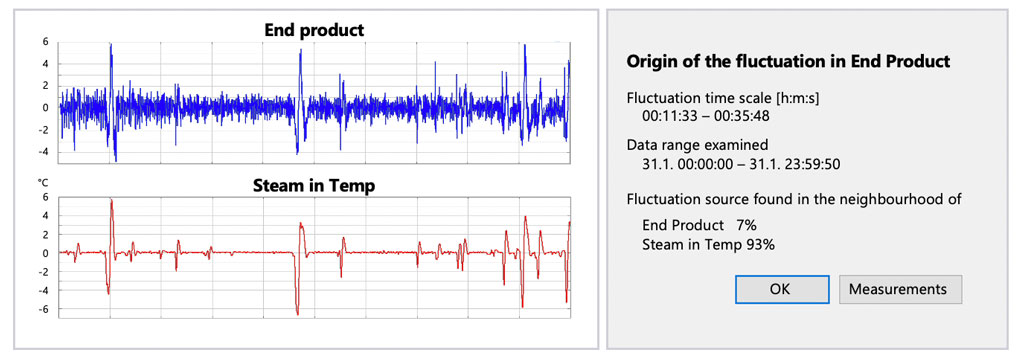

The last step is to diagnose what causes each pattern. For example, you can have Wedge evaluate what causes the strongest fluctuations in the signal (the red one with a period length of 22 min and 39 s). In this example, the data points to the temperature of the incoming steam as the strongest root cause candidate.

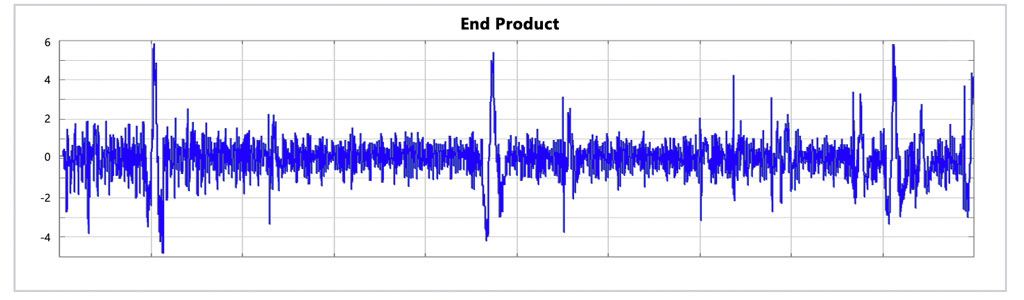

CASE 4: Search for earlier time periods with similarities to the target period

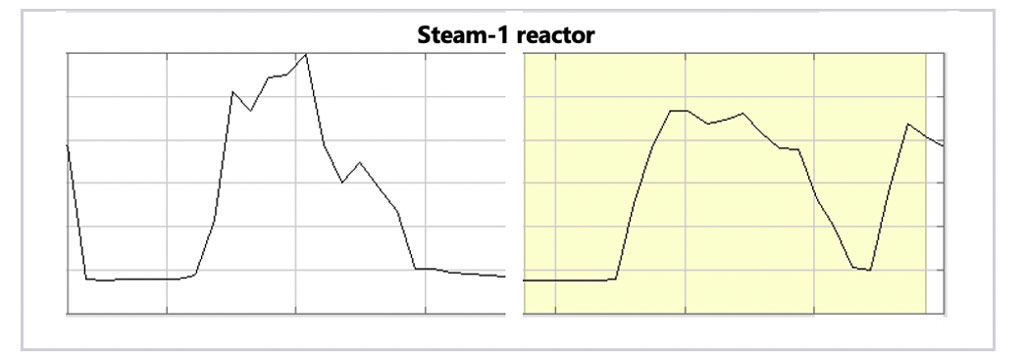

Imagine finding an interesting period of process behavior – let us say, a concentration of an additive chemical is lower than instructed and raw material temperature is in decline. Still, the end product quality remains stable. You might start to think whether such an event or process condition and operating practice has occurred earlier, or if this is a one-off coincidence only.

Wedge will be able to trace different periods in history that have a similar pattern: the same events, process conditions, and/or operating practices as your target period. So, how to trace different periods in history that have patterns – events, process conditions, and/or operating practices – similar to your target period?

Wedge can help you with the task at hand.

You can select the target signal and target pattern behavior. In the picture below, one signal is selected, and the yellow area depicts the period of interest. Wedge studied the history of the signal and found another period when the selected signal behaved in a manner that was relatively similar to the target period. Now you have the main suspects in your hands.

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.