Cleanse & focus the data, while compensating for process delays

Analysis from uncleansed and unfocused raw data is worth nothing. Wedge’s sophisticated toolset for cleansing and refining data allows the user to compensate for process delays, focus the analysis as needed, and prune out invalid data in seconds. With Wedge, you can easily discover the relevant data.

Cleansing & focusing of the data

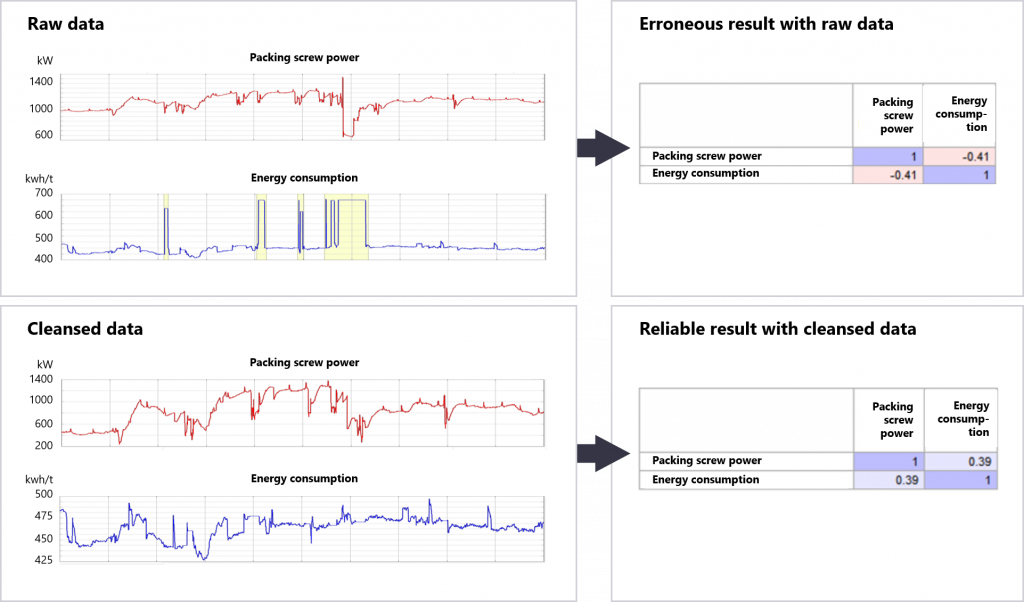

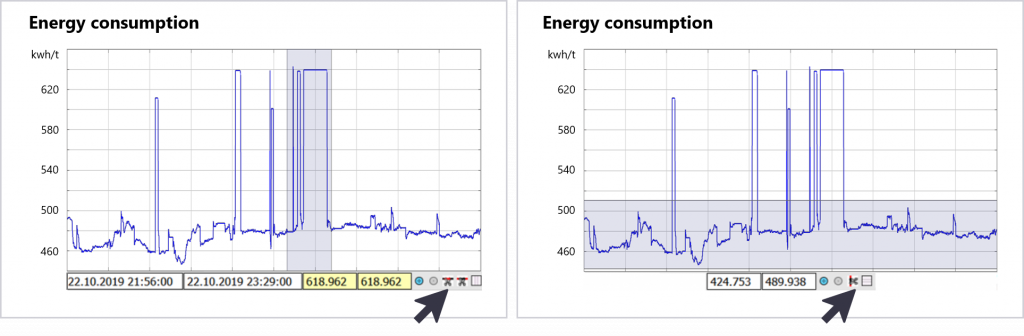

Outlier values in the measurements are very harmful to process studies and often preclude producing reliable results. Easy and fast data-cleansing is the key to effective process analysis.

Cleansing with cutting tools

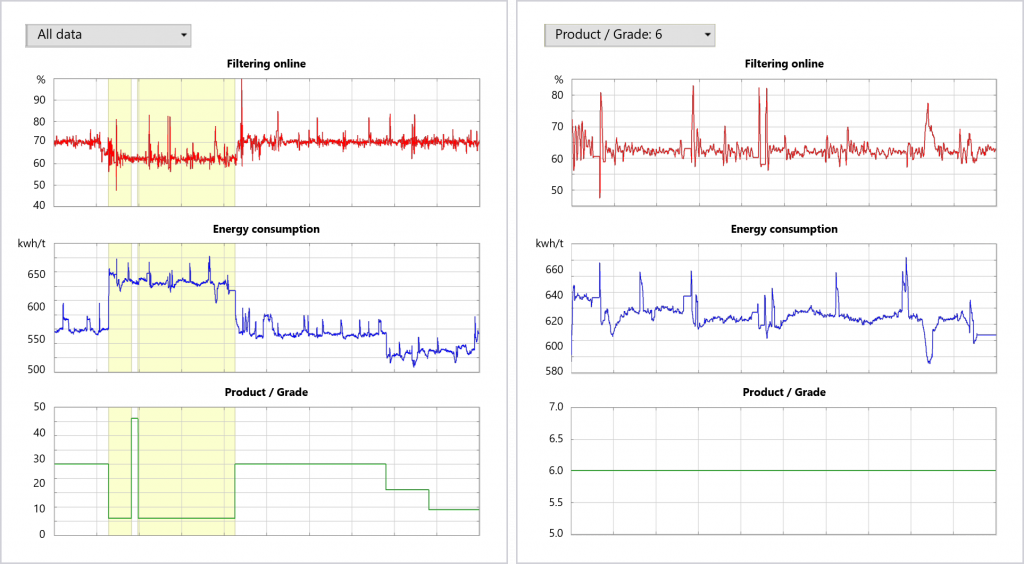

Focusing with filtering tools

With Wedge, you can focus on a specific process status. That might involve, for example, a given product group, type of end product, raw material, or shift.

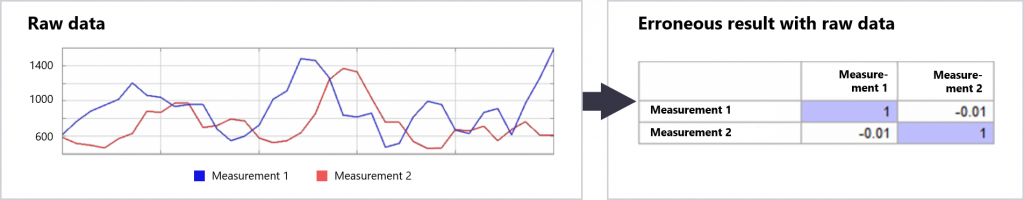

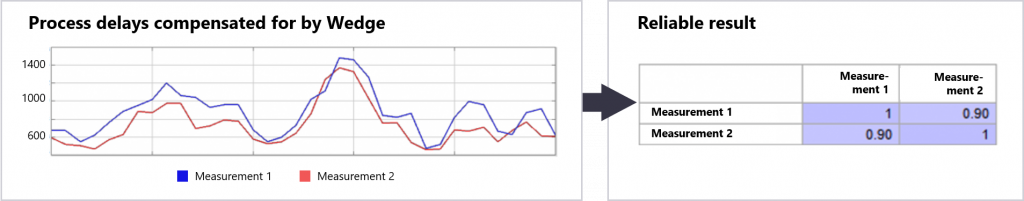

Dynamic process-delay compensation

All process data arrive with delays. If these are not offset or compensated for, they can compromise analyses.

Using a simple time-delay model, you can teach Wedge to compensate for delays: When Wedge knows which process stages are connected to which measurements, the analyses/diagnoses can be automatically adjusted accordingly.

Learn more about Dynamic process-delay compensations >>

Automatic refining of data

All the aforementioned cleansing, focusing, and delay-compensation steps can be automated.

Want to learn more? Contact our sales team!