Holmen expands its Wedge use to Sweden

Holmen Iggesund Paperboard’s mill in Sweden has chosen Wedge as a plant-wide online data analytics platform. Holmen Iggesund’s sister mill in Workington has been a satisfied Wedge customer for over a year now.

“Wedge has given us easy access to our process and product data. It is also a powerful tool for analyzing process data. This helps us in troubleshooting and working with process improvements and product development. Furthermore, it has made us aware of the importance of data quality, which is the foundation of and the key to our way forward working with digitalization and becoming a Smart Site.”

– Peder Hägglund, Technical, Project and IT Manager

The Iggesund Mill is one of the world’s most advanced, fully integrated pulp and paperboard factories. The mill has traditions that stretch all the way back to 1685. It is characterized by pride and commitment, and today around 800 people work together to turn the raw material together into world-class renewable packaging.

Four practical case examples of pattern recognition in Wedge

Wedge makes it possible to use advanced algorithms to recognize patterns in process and quality data. Below, we have introduced four practical applications of pattern recognition that help Wedge users to gain a better understanding of cause-and-effect relationships within the process.

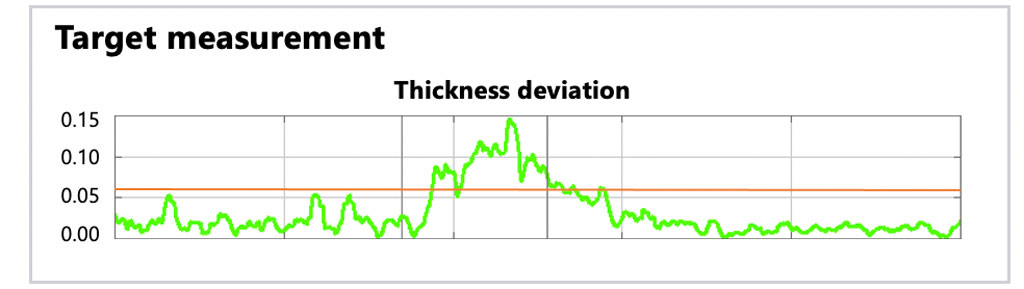

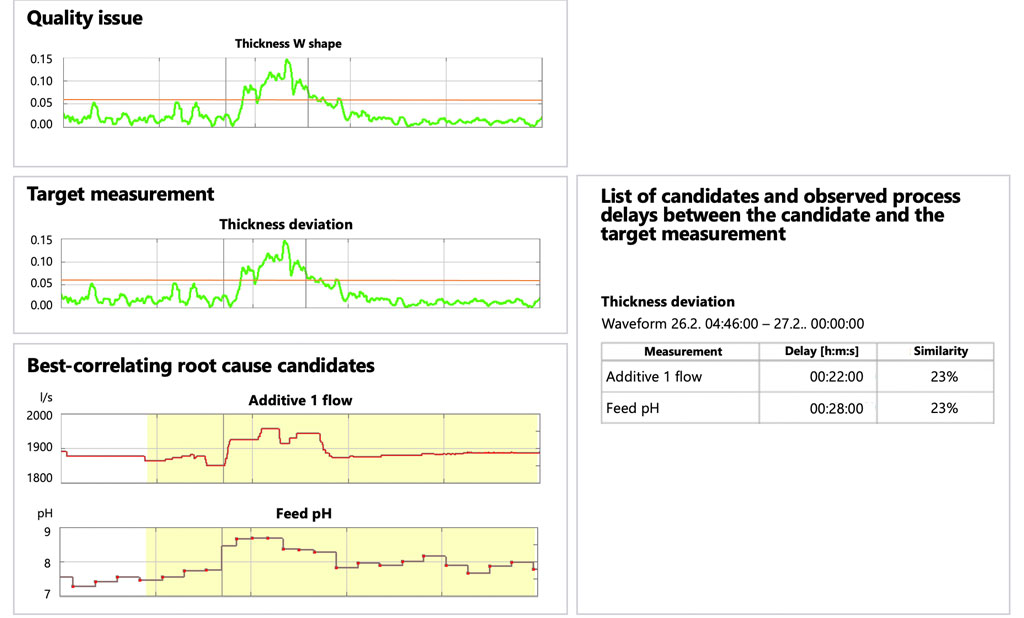

CASE 1: Trace the root cause of a quality issue

There is a quality issue in your process. Deviation occurs in the thickness of the end product, causing waste and scrap. Your first priority is to understand what the underlying causes are that impact the thickness deviation.

Wedge goes through all the other measurements and finds the ones that have a similar or mirror pattern at the same time or before the thickness deviation. As a result, the Wedge system lists the root cause candidates for the quality issue.

As a Wedge user you do not have to worry about possible process delays, since the pattern recognition tool compensates for them automatically.

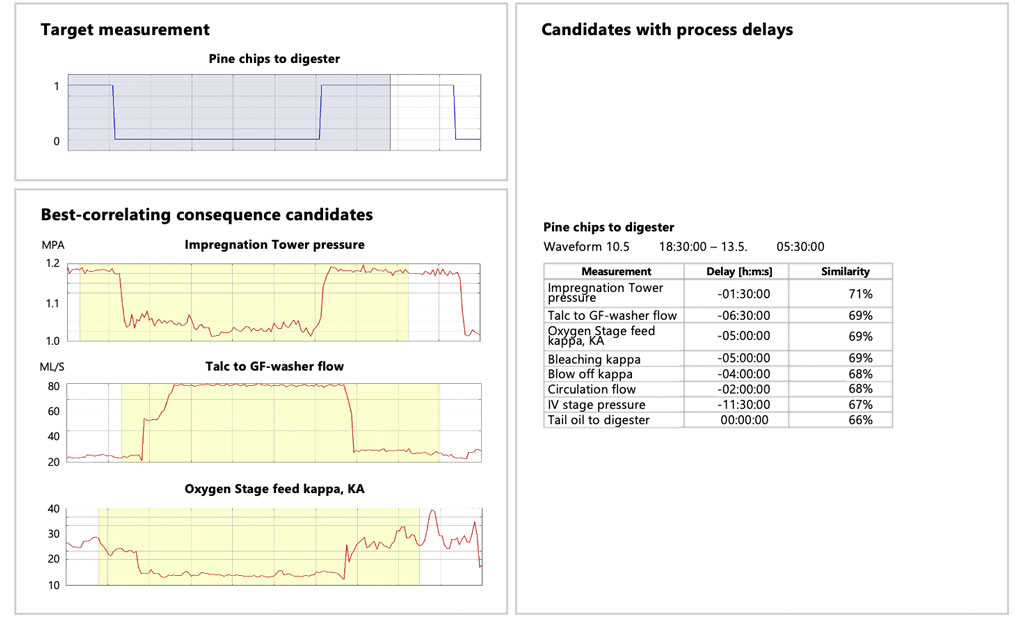

CASE 2: Understand the consequences of raw material changes

Changes in raw material may also affect your process. Wedge pattern recognition algorithms can also help you find those.

Wedge compares the shape of the target measurement (the change of raw material from type one to zero, and back to one) to other signals, and lists the best-correlating consequence candidates with regard to the target measurement and process delay.

This is a great way to learn new things about the behavior of the target process.

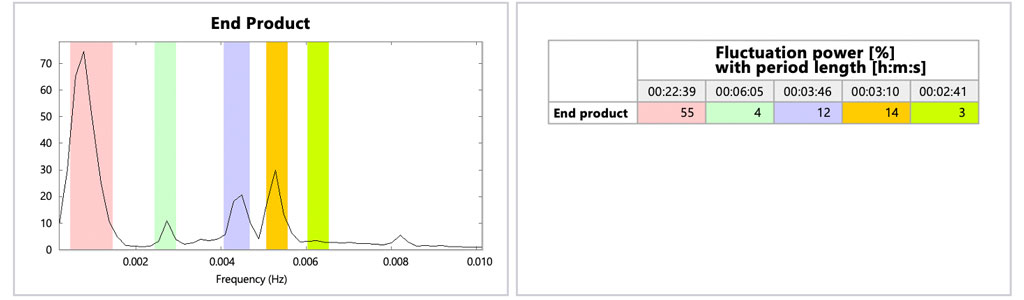

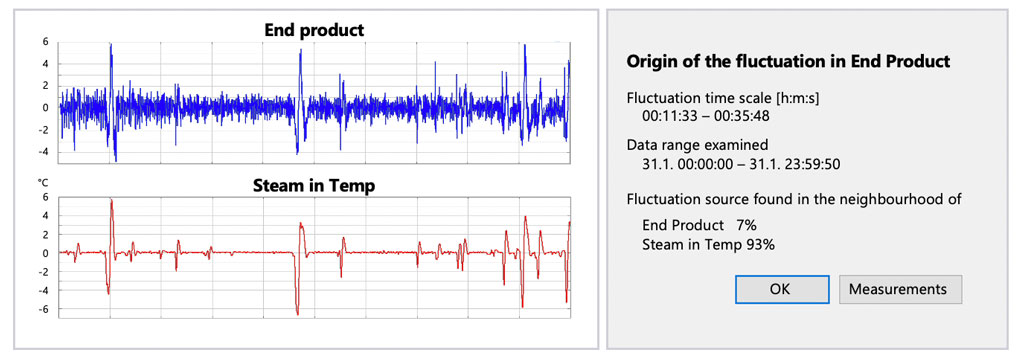

CASE 3: Figure out what causes periodic fluctuations

A single peak in a signal and/or a change in a level are easy patterns to notice and trace. But what if your target measurements fluctuate strongly but it seems to be random? Or the pattern does not look clear or there are several independent patterns having an impact at the same time? Sounds complicated, but with Wedge it is not.

First, Wedge helps you by isolating different patterns from the signal. The system shows what kinds of fluctuation patterns can be found and the relative power of each pattern. In practice, we get to know whether there are periodic fluctuation patterns in the data, what the period lengths of the identified patterns are, and which fluctuation is the strongest.

The last step is to diagnose what causes each pattern. For example, you can have Wedge evaluate what causes the strongest fluctuations in the signal (the red one with a period length of 22 min and 39 s). In this example, the data points to the temperature of the incoming steam as the strongest root cause candidate.

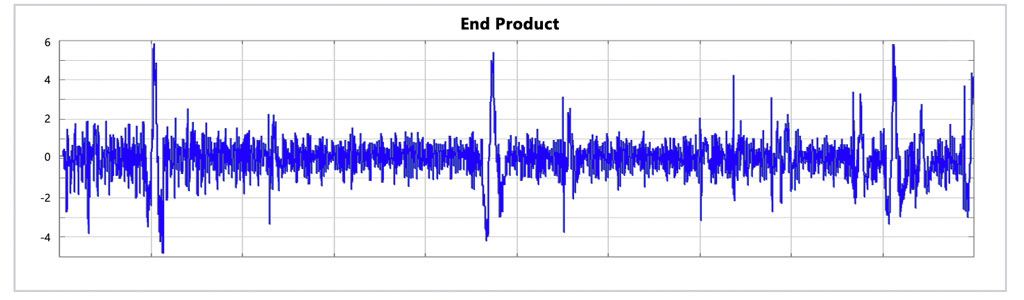

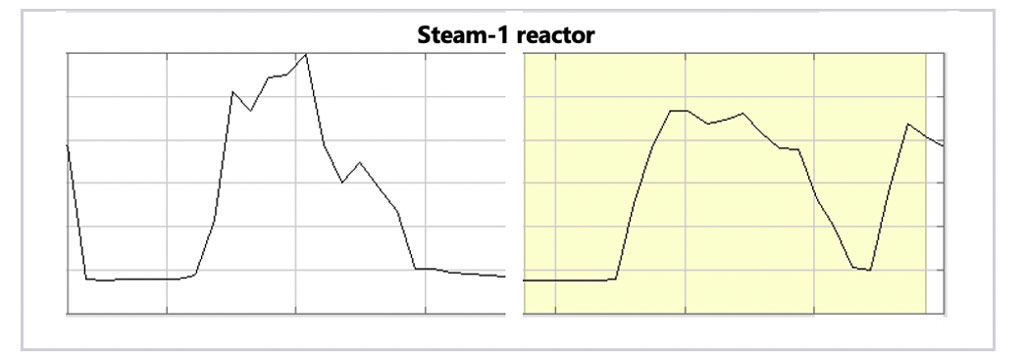

CASE 4: Search for earlier time periods with similarities to the target period

Imagine finding an interesting period of process behavior – let us say, a concentration of an additive chemical is lower than instructed and raw material temperature is in decline. Still, the end product quality remains stable. You might start to think whether such an event or process condition and operating practice has occurred earlier, or if this is a one-off coincidence only.

Wedge will be able to trace different periods in history that have a similar pattern: the same events, process conditions, and/or operating practices as your target period. So, how to trace different periods in history that have patterns – events, process conditions, and/or operating practices – similar to your target period?

Wedge can help you with the task at hand.

You can select the target signal and target pattern behavior. In the picture below, one signal is selected, and the yellow area depicts the period of interest. Wedge studied the history of the signal and found another period when the selected signal behaved in a manner that was relatively similar to the target period. Now you have the main suspects in your hands.

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.

Process knowledge and efficient data use are key to energy efficiency

Industry processes traditionally generate a lot of data, but from an energy-efficiency point of view, it may not be relevant data or the right kind of data.

Energy use does not always impact production, so even significant shortcomings in energy efficiency do not necessarily disrupt the core process at a manufacturing plant. Energy guzzlers are easily missed.

How to improve energy efficiency at a production mill

Two things are needed to improve energy efficiency: the right data and expertise in both processes and data handling.

Elomatic offers expertise in both areas. Elomatic combines its measurements with the customer’s data to help the customer make their energy use more efficient. Jukka Summanen, Leading Expert and Development Manager at Elomatic describes the challenges of data use:

The customer may have collected a lot of data but is not sure how to make the best use of it. Usually, the data needs to be cleansed and sorted to really make it useful. Process knowledge is key to sensible and reliable data analysis. Without process knowledge, data is useless.”

Handling energy data is a broader process than handling process data

Process data is often handled from the point of view of production, to improve production efficiency or by investigating an individual problem and its root causes. When energy data is analyzed, the data mass is often larger and it is monitored over a longer time, for example, a year. The data can be analyzed against other variables, such as weather changes. Energy data analysis also makes use of statistical and range analyses.

One important measure is energy balance, which reveals how much energy enters the plant, how it is consumed, and how much energy leaves the plant unutilized.

Unlock the power of Wedge for industrial data analytics

The benefits of energy efficiency

Simple discoveries often result in significant savings. Proper data analysis can help track devices that are on for no reason, oscillating process controls, or malfunctioning heat transfer devices, for example.

Refining energy consumption data into information about specific types of consumption helps track and develop energy efficiency from a type-specific viewpoint. This makes it possible to obtain product or batch-specific information about environmental effects, which creates a premise for setting carbon neutrality goals.

In the future, it will be easier to predict status and efficiency in production, but this requires that the right data is collected and analyzed with competence.

Using the right tool increases efficiency significantly

An efficient and easy-to-use data analytics system makes process analysis easier and produces better-quality analyses. It enables companies to make changes that improve energy efficiency based on knowledge, not guesswork.

The tool of choice for Elomatic is Wedge, Trimble’s process diagnostics tool.

Team Leader for Efficiency Solutions at Elomatic, Jussi Jääskeläinen, explains why:

If we could go by trends alone, we would not need Wedge, but in our line of work it is essential that we can sort data by a specific quality or time period. What is more, it is quick; you can do it with one click. Other products cannot do that.”

The stages of improving energy efficiency

This is how you can improve energy efficiency in your own company:

- Make sure you are measuring the right things

- Monitor the measurements and energy balance over a long time period, such as a year

- Cleanse and sort the collected data, and analyze the results

- Use the data to establish monitoring for significant energy consumers, with target values

- React to anomalies, make the required plans and execute them

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.

The most common user scenarios for data analytics with Wedge

When we categorized the most common Wedge user scenarios, the following cases came up. Different user scenarios are usually linked together; for example, the situation awareness view also includes the possibility to drill down into very detailed analysis.

Situation awareness | Know exactly what is happening in your processes

Wedge offers ready-made views for situation checks with just one click.

- Diagrams & Dashboards

- Center Lining

- Predictions & Forecasts

- Standard views

- Morning meetings

- Shift change meetings

- Hop-in to the control room for “what’s up”

Ad-hoc need for process data | Get fast facts to support your decision making

Simple and fast data retrieval, cleansing, and analysis – the basics of Wedge use.

- In the middle of a meeting

- In process operations when something is abnormal

- In process operations: how we did it earlier

- In process operations: when I change this parameter, what are the consequences

Optimization and development | Learn how to improve processes and operations

Process status comparisons and analysis are easy to do with Wedge.

- What is the difference between a good and bad operation window?

- Finding best practices

- What are the effects of bad practices?

Deep analysis | Find the root causes even in the tricky cases

Data analysis-driven projects benefit from Wedge.

- Development projects

- Troubleshooting project

Read more about how widely Wedge is used at different mill sites >>

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.

Why process analytics with Wedge is so popular at mill sites

It is an outdated belief that data utilization is the job of only a group of dedicated people, like development engineers. With a well-designed diagnostics tool, process data analytics is (almost) for everyone.

Wedge is a well-known process data analysis and diagnostics system that has been in use for over 25 years. It is designed to serve a broad range of different user groups from process operators to mill managers and to help in various use cases.

So, it took us by surprise when one of our customers once told us that their mill site only has a handful of Wedge users because they don’t have that many data experts in-house to do data analysis. We are great believers in facts, so we checked our user statistics to see whether that is really the case.

Average of 50 active Wedge users per mill site

Based on data gathered from 25 different mills, the number of weekly active users varied from 10 to over 100 users per site, with the average number being 50 active users per site. This was even higher than we expected, and we were left thinking that there must be ways to utilize Wedge that even we are not aware of. Naturally, we wanted to find out in more detail what the common, and even the more unconventional, Wedge user scenarios are.

It is incredible that people do data analysis without even noticing that what they are doing is data analysis.

While studying the issue, we came across various comments underlining the fact that Wedge has increased data usage and democratized analytics.

With the help of Wedge, people select data, refine it, and run statistical comparisons with no hesitation at all. The more the culture at mills encourages data-driven decision making, the faster people adopt the Wedge system.

Read more about the most common user scenarios for data analytics with Wedge >>

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.

We are hiring: Development Engineer

We are looking for a new member to our Wedge team in Espoo, Finland.

If you can see yourself as our new Development Engineer developing our process diagnostics system Wedge as well as Wedge related new applications, especially distributed Big Data acquisition, Storage and handling Tools and Applications, don’t wait too long but apply now.

Center Lining helps optimize plant operations and induces continuous improvement

Process stabilization is critical for all industrial processes to ensure uniform quality and low production costs. Center lining is a commonly used term for keeping key process variables at desired levels and optimizing them further.

Center lining is not a strictly defined methodology, but there are certain steps that should be followed in a specific order. When you have completed all steps, you can repeat the process.

The five stages of center lining are:

- Identify key variables

- Create variable limits

- Monitor key variables

- Monitor long-term key variables

- Review limits

Process knowledge is required to determine key variables and limits

The first step is to identify the key process variables that affect product quality the most. You need to analyze a long time period and find the times in which quality has met the specified limits and the production rate has been high enough. When you find a suitable time period, you should analyze process data to find key variables. The easiest way to do this is to search the measurements that correlate best with the quality parameters.

The next step is to define the desired levels for the key variables. A standard Statistical Process Control (SPC) method approach is suitable for this: 1) You select the times when the process has worked well, 2) cleanse the data, and then 3) calculate the average and standard deviation values based on that data. Then, for example, three sigma limits can be calculated. Limits must always be dynamic depending on the state of the process.

Unlock the power of Wedge for industrial data analytics

Visualization is the key to utilizing SPC limits

It is important that SPC limits and violations are visualized in a user-friendly format. This helps the operator to quickly identify all key variables that are outside the limits. The visualization can consist of gauges or traffic lights to show the current situation in the process, and trends to visualize longer-term stability.

To support operators further, it is recommended that KPI values with a longer perspective are also made available to the operators. One simple solution is to calculate the portion of KPI values that have been within the limits for the previous 24 hours, one week, or some other period.

The system should also help you find out why the key variables are outside the limits. Operators need to know what is causing the limit violation and what they should do next to fix the issue.

Always aim for better

Process development is a continuous task. After the production is stabilized, it is possible to take the next step to tighten the limits to produce even better-quality products consistently. Simultaneously, you can aim to reduce energy consumption and/or reduce raw material costs.

After these steps are taken, you can start the center lining cycle again. Repeating the process is important because optimizing the previous key variables enables you to find more key variables to optimize the process further.

One further aspect to consider are the tools that support the process. Today’s information systems at mills contain a lot of data, and the data that concerns processes and quality is often scattered across several data sources. Without proper data handling methods, center lining is too laborious to implement, and the full potential of process equipment is not utilized. The recommended solution is to use process data diagnostics software that helps you process data effectively and perform the center lining steps efficiently.

This article is based on our white paper published at Papercon in 2019 under the name Smart Paper Machine Analysis Reveals Center Lining Truths. Download the original paper.

Want more insights?

Want more insights?

Our sales team is full of data analysis experts ready to help you. Learn more about Wedge industrial data analytics tool.

New customer: Holmen Iggesund in Workington

Holmen Iggesund selects Wedge for plant-wide deployment at its Workington mill.

Workington Mill is an integrated pulp and paperboard mill. Since 2013 it has been powered entirely by fossil carbon-free bioenergy. Bleached mechanical pulp is processed to suit the special demands of paperboard manufacture and is combined with purchased bleached chemical pulp into a multi-layered board construction which is ideally suited to the demands of modern paperboard packaging. Continuous development and adaptation to customer needs and expectations are essential for success in a highly competitive market.

Join the Wedge User Forum to learn more about the enhanced tabular report and other additional features

Like you probably already knew, it’s easy to create grade-dependent reports with Wedge by using the tabular report feature. You can select any measurements and any time period to create a tabular report based on aggregation criteria like the grade codes. You might also have noticed the limitations of this method: the report only shows the grade-dependent average values of the measurements, and the results can’t be copied for further use.

This problem has now been fixed with an enhanced version of the tabular report feature. The enhanced version enables you to calculate other statistical parameters like the minimum, maximum, and standard deviation values of the measurements.

You can find this and many other additional features on the Wedge User Forum.

Data transfers for greater value from the data

This enhanced version enables you to easily copy the results to other software for further use. This type of data transfer is important in order to get more value from the data and to share the process knowledge. Quite often there seems to be a need to aggregate process data and transfer the results to other systems. This workflow can be automated with Wedge’s DSA system (Data Stream Analysis) described in an earlier newsletter.

Split data reports

With a combination of Wedge’s data filter menu and this enhanced tabular report feature, it’s also possible to create a report where the data is split based on two aggregations at the same time, for example, grade and shift number. This is also a frequently requested feature.

Stay tuned for the latest developments

The Wedge team frequently releases prototypes of potential new features on the Wedge User Forum. So be active in testing them out and giving us feedback. Cooperation will help us implement the best possible features in Wedge that make your daily work easier.

Introducing ForestBioFacts – new digital learning environment

Do you want to know more about wood-based products, technologies, or sustainable forest management?

Have a look at the free Introduction to forest-based bioeconomy at ForestBioFacts website that opened today.

ForestBioFacts is the new digital learning environment for professionals and students in forest-based industries. Trimble Forestry has been part of the content production and one of the main sponsors.

We are happy to welcome you to develop your professional skills in forest-based products and technologies!

Learn more at forestbiofacts.com/